DSIGNER 2022.0 R2

Explore the key features of DESIGNER 2022.0 R2

Kontakta oss

DESIGNER 2022.0 R2, the latest release of Hexagon’s CAD for CAM application for smarter manufacturing, features several new enhancements:

General improvements

DESIGNER 2022.0 R2 features new user interface enhancements to improve interactions with every command and to the macros so that they are even more user-friendly. All these developments have been implemented to optimise the process workflow and the user experience, bringing additional benefits such as process automation, standards definition and ease of use.

Modelling and surfaces

Extra tools have been added in DESIGNER 2022.0 R2 to expand the modelling capabilities and performance. The usability workflow has been optimised, improving time reduction when performing modelling tasks to prepare parts for manufacturing. These enhancements enable users to set up any part quickly and easily, resolving many issues previously difficult to achieve or requiring multiple data exchange with other applications. The surface module offers the ideal tools for editing and preparing complex freeform geometry for advanced manufacturing.

Translators

DESIGNER 2022.0 R2 continues the tradition of bringing updated format support and continued enhancements and fixes to further improve the robustness and performance of 3D modelling and interoperability. The component that provides the appropriate ‘converters’ for the different CAD formats is improved. Additional file formats have been added to extend synergies with other products from the Hexagon production software portfolio. As a standard practice, all the translators have been updated to guarantee the highest possible level of compatibility with other systems.

REcreate

DESIGNER 2022.0 R2 features improvements to the reverse engineering module, REcreate, which have been designed to simplify use of the software as well as reducing the need for extra clicks for overall productivity improvements. The solution provides powerful tools to quickly create valid models and features, offering a massive reduction in time and effort. The functionality in REcreate lends itself to various applications across different industry verticals, as well as offering enhanced technology and synergies with other Hexagon products.

Electrode

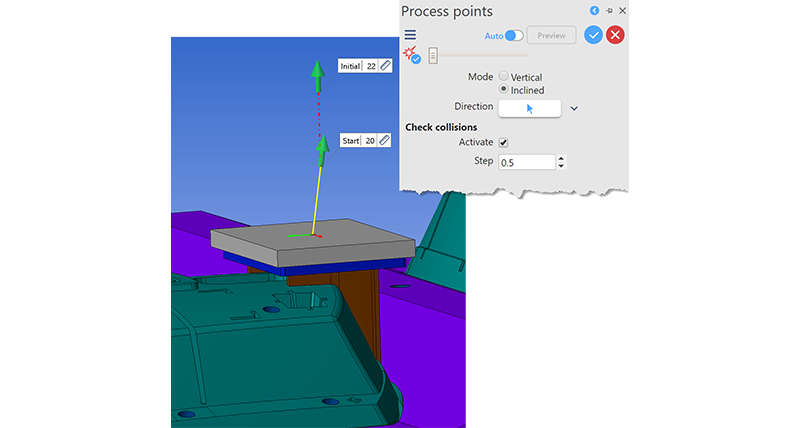

Continuous enhancements to the electrode module in DESIGNER 2022.0 R2 make this functionality more powerful and intuitive. The management of the process direction has been improved to make it easy to use and customise the process direction of electrodes. This implementation offers users a complete solution for electrode design that now also includes simulation/check collision and measuring information for the CMM.

Sheet metal

The sheet metal module offers a flexible database for materials and bending data. This database, fully linked to Metrology Asset Manager, allows the user to describe the bending parameters in a way that suits their way of working. The benefits are a high level of automation and full control over the accuracy of the unfold calculations. Many of the existing functions have an improved and unified user experience, shortening the learning curve. New commands enhance the engineering of the part and allow users to spot problems on the unfold in advance, ensuring smooth execution of further manufacturing activities.

-

DESIGNER 2022.0 R2 videor

Advanced Selection

Improvements have been made to element and face selection in this release. Users now have better control while filtering and selecting, and can select elements by name and partial name, by part properties, by geometry properties such as volume and much more. Face selection has been enhanced to enable Users to select similar faces on all bodies in the model.

Direktredigering

Användarna kan nu göra ändringar i modellerna utan att behöva köra några kommandon alls. Klicka bara på en yta för att ändra blandningsradie eller avfasningsstorlek, eller välj en kant eller ett trådramselement för att ändra längden. Detta möjliggör snabba modifieringar för snabb modellering.

Redigera Ångra-historik

Ångra-historiken sparas nu med filen och kan redigeras. Det ger möjlighet att redigera tidigare skapade funktioner och operationer utan att behöva ommodellera delen eller börja om från början. Detta påskyndar modelleringsprocessen och minskar behovet av extra, onödiga åtgärder.

Connection with ESPRIT

DESIGNER and ESPRIT are now connected applications. ESPRIT can read native DESIGNER files and DESIGNER can send models directly to ESPRIT using the Send to CAM function. If a DESIGNER file that's been opened in ESPRIT is modified, the model can be updated rather than reloaded. ESPRIT mouse controls can be set in DESIGNER to improve the transition when working with both applications.

REcreate - Align

Improvements have been made to the align command to enable much more control when aligning elements. Users can now use wireframe elements, cylinders and workplanes to aid the alignment process, as well as performing a simple best-fit to improve an existing alignment.

REcreate - Mesh Features

The new Mesh Features command automatically recognises features on a mesh. Either create solids and surfaces directly using this command, or split the mesh into its individual features for downstream solid and surface creation.

REcreate – Jämför och validera

Kommandot Compare cloud/mesh (jämför moln/rutnät) har förbättrats och användarna kan nu se standardavvikelsen för resultaten i färgstapeln på skärmen. Dessutom har jämförelsefunktionen lagts till geometrin från rutnätskommandon, såsom plan, cylinder, kon från rutnät osv. och även kommandot rutnät till yta. Detta säkerställer att ytor skapas inom toleransen vid skapandet för snabbare och mer exakta resultat.

Elektrod – simulering

Simuleringsverktygen i elektrodmodulen har förbättrats. Det går nu snabbt och enkelt att definiera anpassade processriktningar och simulera för att se till att det inte finns några kollisioner.

Plåt – Hörnavlastningar

Hörnavlastningsfunktionerna i DESIGNER har konsoliderats och gjorts kraftfullare och enklare att använda. Tillägget av en fyrkant fullbordar modellutbudet och skapar en perfekt kvadrat i den utfällda delen.

Plåt – Böjavlastning

När du lägger till böjar lägger DESIGNER automatiskt till en böjavlastning vid behov. Detta gör det enkelt och snabbt att lägga till en ny fläns.

Plåt – Materialformer

DESIGNER gör det möjligt för användaren att specificera ”Material Form” för en del – dvs. vad delen kommer att tillverkas av. På så sätt separeras plåtdelarna från rör och stänger och från de köpta delarna. Efterföljande automatiska processer, som utfällning, tillämpas då endast på de berörda delarna. Vid användning av Send to CAM skickas endast plåtdetaljer till RADAN för integrering och vid användning av nya Send to Radtube skickas endast rör och stänger till Radtube för bearbetning.