MERCURY FX

Upgrade your horizontal arm for smarter manufacturing

Would you like to know more?

The MERCURY FX is the ideal solution for horizontal arm users that want to leverage their current assets when adopting new measurement technologies. Designed to be fitted onto an existing horizontal arm CMM base table, even if it is a non-Hexagon system, the MERCURY FX offers all the long-term performance advantages of a new CMM system, while minimising disruption to busy workplaces during installation.

The MERCURY FX combines mechanical accuracy with high repeatability and its open architecture, robust mechanical frame and automatic axis motion make it ideal for loading and unloading even the heaviest medium, large and very large parts. Versatile, the MERCURY FX offers a choice between using tactile sensors, non-contact scanners or taking a multisensor approach. And because it operates the latest metrology software, including Hexagon’s PC-DMIS, it enables companies to better capture, analyse and make efficient use of metrology data.

Choose from three versions:

MERCURY FX - Runway

MERCURY FX - Runway

- Ideal for measuring medium to very large workpieces

- Arms on guideways decoupled from the base table

- Guideways can be installed on or flush to the floor for better ergonomics

- Single, dual or multiple arm configuration

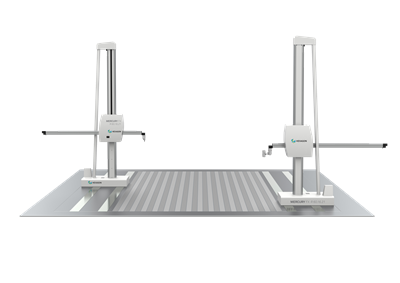

MERCURY FX - Console

MERCURY FX - Console

- Ideal for inspecting medium-sized components

- Full table surface is available for measurement

- Integration in existing base table

- The system is also available with a base table

- Single or dual arm configuration

MERCURY FX - Top Mounted

- Ideal for measuring medium to very large workpieces

- Arms integrated into the existing work table on the top position.

- Guideways can be installed on or flush to the floor for better ergonomics

- Single, dual or multiple arm configuration

The MERCURY FX CMM is compatible with Hexagon’s controllers, which enhance application flexibility and support a multisensor system operating a full range of tactile and non-contact sensors. The RC line of controllers best supports retrofits and the DC800 controller is designed for new installations.

Features and benefits

Installation Versatility

The MERCURY FX can be installed on existing steel, cast iron or granite base tables from a wide range of horizontal arm manufacturers.

Compatible with Hexagon software and sensors

The MERCURY FX is compatible with Hexagon’s tactile, non-contact sensors and multisensor systems, as well as Hexagon’s metrology software, which optimise horizontal arm performance and usage.

Robust and repeatable

The MERCURY FX combines mechanical accuracy with high repeatability, a robust mechanical frame and automatic axis motion to measure even the heaviest medium, large and very large parts.

-

Download

-

BrochureHorizontal Arms

-

BrochureSheet metal inspection solutions in automotive

-